Designing a high-tech product, from POC to mass production, with turnkey industrialization or support during specific stages.

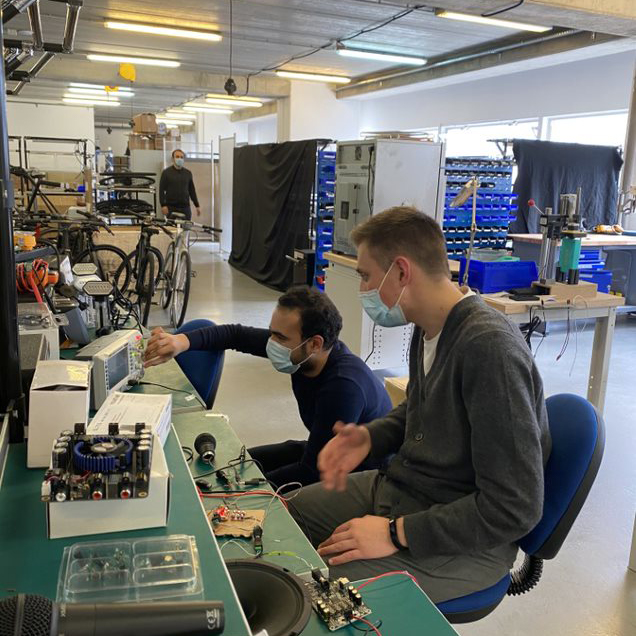

POC & prototyping

Full design of a POC or a unit prototype: mechanical, electronic, software and integration + debugging. Using the micro-factory’s prototyping workshop. For those who want to validate a proof of concept, to produce a functional prototype.

Carry out a POC or a functional prototype

- Reaching your market

- Validate a function

- Validate a concept

- Market proof

- Trade shows & marketing presentations

- Prepare the development and full industrialization of a product

Requirements and preconditions

-

MRD – high-level specifications

Deliverables

- POC

- Prototype

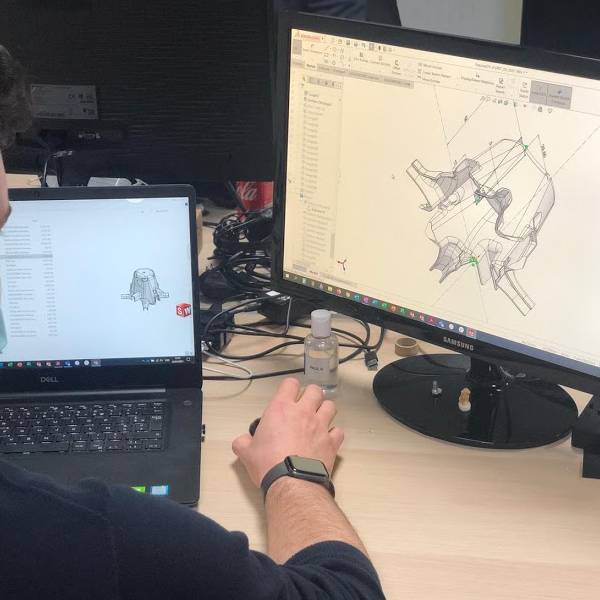

Product development (PRD EVT DVT PVT)

Product development and industrialization according to the EVT DVT PVT iterative cycle methods. Turnkey industrialization or support on a specific stage up to pre-production and technology transfer.

Industrialize your product or work on specific steps

– Writing of specifications : PRD

– 2D & 3D mechanical

– Mechanical, electronic design review

– Low level & application software development

– Electronic board development

– Sourcing, evaluation & qualification of suppliers

– BOM and BOM consolidation

– Design

– DFX ( DFC, DFA DFP DFM…)

– Certification: support in the process of obtaining certification

Requirements and preconditions

- POC

- Functional prototype

- PRD

Deliverables

- Preseries

- Industrial product

- IRD (Industrial requirement document)

Preseries

Pre-series production in the micro-factory using the Kickmaker systematic method. Pre-series debugging. Industrialization file.

Produce pre-series and debug and improve the industrial file.

- Qualification and calibration of tooling.

- Qualification of the assembly line and ranges.

- Qualification and training of operators.

- Development of test benches & qualification.

- Supplier management / month.

- Supply chain management / month.

Requirements

- PRD, POC, prototype.

Delivrables

- Pre-series / update of the industrial file / of the IRD.

Transfert to the series

Design transfert to the EMS, lines production set up and supervision of the start of production.

Design transfert & production launch.

- Sourcing and partner selection (continued work).

- Support for the ramp-up.

- Review and improvement of the supply chain.

- Setting up NPI technical and human resources.

- Assembly and quality testing.

Requirements

- Industrial file / IRD.

Deliverables

- Series & industrial file

Qualification and production test benches

Creation of customised production test benches.

Develop the qualification systems and sub-systems and the production test facilities to measure the quality of the products on the line or at the end of the line.

- Development and design of customised test benches.

- Sourcing.

- Bench specification.

- Installation of test benches.

- Bench integration and commissioning.

Requirements

- Industrial file / IRD.

Deliverables

- test bench / test reports / test plan.