It is often complicated when starting a hardware project or the ideation of a hardware project, whether you are an investor or advisor to startups, or simply curious, to find clear information about the industrialization of a high-tech product. This is what we will try to do in an introductory, concise and non-detailed way in this article.

As explained in the previous article, industrialization is a process that must be robust, reliable, reproducible and repeatable and must allow a functional prototype to become a manufacturable product. The verb “industrialize” means to produce or exploit, using industrial methods.

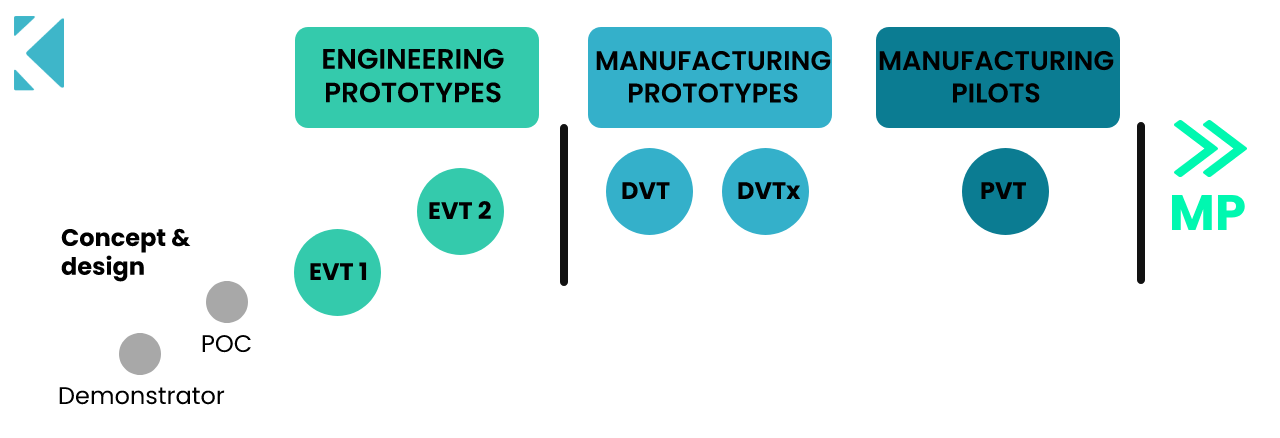

There are, as always, several methods, but the one we will talk about today and recommend to you is composed of several iterative and successively carried out steps, called EVT DVT PVT and designating the different levels of maturity of the system to be manufactured and the different stages of the manufacturing process. Industrialization starts after the POCs for Proof Of Concept (feasibility of functions) and sometimes continues even after delivery via continuous improvement processes.

EVT

EVT means Engineering Verification / Validation & testing

-> This is the validation stage of the technical solutions.

The EVT combines “looks like” and “works like” prototypes in a single demonstrator, and with temporary parts: dupli silicone moulds, or soft tooling parts printed in 3D, PCBA prototype…

The EVT is used to verify that the prototype works with all the functionalities defined in the PRD and that the design meets the purpose of the object. It is necessary to make sure that the function has not been misused.

Quantities of EVT prototypes: they depend on the complexity of the product and the cost of the bill of material (BOM) (3 to 10)

DVT

DVT means Design Verification / validation & testing

-> This is the product validation step.

The DVT phase is started when it is certain that the design will work. The 3D and 2D plans are completed, the materials and a test plan are defined. The DVT product is intended to be a final production design configuration, with components from the production process (final tools/moulds). The design is tested with real parts, with real dimensions and with materials that are close to the final materials.

For this purpose, the product is manufactured in a limited number of copies and these copies undergo a battery of tests (drop test, heat, wear…). It is essential to ensure that the product will meet cosmetic (appearance) and environmental requirements.

This stage is also very much linked to certifications and contact with suppliers.

In short, we assemble, test, iterate until the design is suitable. At the end of the DVT, a validation document of all the tests must be done and the 3Ds must be frozen.

Quantities: they depend on the complexity of the product and the cost of the bill of material (BOM) (50 to 100)

PVT

PVT means Product – Production Verification / Validation & Testing

-> This is the validation step of the production line (pre-series -> first run) :

The PVT step is the last construction of the product. The manufactured units are supposed to be sold to customers, if they validate all the tests. The parts are close to those that will be used for the series, but still assembled by hand. In general, the PVT is the direct transition to the ramp-up and mass-production phase. A pilot production line must be established to check that there is no failure at any stage of the production line. The PVT phase validates the assembly process: process speed, quality, control points and test means, calibration tools and production monitoring, increase in worker skills, packaging, supply flow and logistics… Continuous improvement processes (PDCA, FMECA manufacturing, etc.) are set up and will enable future developments and optimisation. This phase is more related to operations than to development.

Quantities: they depend on the complexity of the product and the cost of the nomenclature (100 to 1000).

And after? Time for mass-production